"Popping the Hydrogen Bubble" by David Turver

"The UK Hydrogen Strategy is a triumph of financial engineering and PR spin over the Laws of Thermodynamics"

The following is an excellent analysis of the UK’s allegedly “green” hydrogen strategy which is being pushed upon us as the latest scheme that will help them meet the political rhetoric which they refer to as “net zero” and/or the “energy transition.”

Given that wind weasels such as newbie “developer” Bute Energy and their financial backers, Copenhagen Infrastructure Partners (CIP) are either already in the game as CIP is, or have companies such as Bute Hydrogen Limited (registered in Edinburgh from whence Bute Energy have invaded Wales), I see it as an extension of the wind Ponzi scheme. After all, the hydrogen referenced becomes “green” when it is produced from not clean nor green unreliable industrial wind turbines.

Popping the Hydrogen Bubble

The UK Hydrogen Strategy is a triumph of financial engineering and PR spin over the Laws of Thermodynamics

By David Turver • 11 March 2023

Summary

As part of their efforts to achieve Net Zero and improve energy security, the Government is pushing ahead with its Hydrogen Strategy. They are splurging £240m on lots of projects to produce, store and use “clean” hydrogen in the hope of creating a new market. The trouble is that hydrogen is not a primary energy source so in a free market hydrogen would always cost more than the fuels used to produce it.

A number of the methods for producing hydrogen are touted as environmentally friendly even though such claims are dubious. For instance, studies have shown hydrogen from solar power may emit as much CO2 as hydrogen produced from methane. One flavour of green hydrogen, produced from biomass, requires thousands of trees to be chopped down which hardly kind to the environment. The cheapest way of producing clean hydrogen is using methane or natural gas, not exactly the fuel to be using to improve energy security unless the Government also allow fracking to restart.

Many of the hydrogen applications the Government is promoting most are the least feasible and most difficult to achieve, such as domestic heating, balancing the grid and transport. Its plans for large scale, long term storage also seem to be stalling.

The calculations showing the lowest costs to produce low-carbon hydrogen rely on fantasy financial engineering. For instance, the electricity needed to produce hydrogen from curtailed wind power is assumed to be free, even though the curtailment costs will be added to our bills. They even say that hydrogen produced from biomass will cost less than nothing even though it is the least thermally efficient process. They achieve this conjuring trick by paying the producer for carbon credits at nearly 10 times the cost of CO2 capture and storage.

Their hydrogen business model provides opportunities for additional subsidies to be layered on top of the already generous subsidies paid to producers of intermittent wind and solar energy. This is white collar welfare on steroids, to be paid for by the poorest in society. Thankfully, some MPs are already pushing back on the poor science and subsidies amounting to white-collar welfare on steroids inflating this hydrogen balloon. It is time to pop the hydrogen bubble.

Introduction

Back in August 2021, the Government published its Hydrogen Strategy as part of its drive towards Net Zero. In its December 2022 update, the Government added energy security as a critical factor. Among other things, the strategy called for the development of 5GW (since updated to 10GW) of low carbon hydrogen production capacity by 2030. To put that in context, 10GW is roughly twice the current operating capacity of our aging nuclear fleet. The Hydrogen Strategy says the Government will put £240m behind its Net Zero Hydrogen Fund and a UK Low Carbon Hydrogen Standard. Jon Butterworth, chief executive of National Gas has said that plans are being drawn up for hydrogen to be between 2 and 5% of the gas in the transmission network by 2025. Moreover, the National Grid ESO has put considerable emphasis on hydrogen in all of the Future Energy Scenarios to deliver the Net Zero target by 2050.

However, a report to the House of Commons Science and Technology Committee has concluded that “any future use of hydrogen will be limited rather than universal” and “we do not believe that it will be the panacea to our problems that might sometimes be inferred from the hopes placed on it.” In addition, the new Secretary of State for Energy Security and Net Zero, Grant Shapps has run into trouble with his own MPs opposed to imposing a new levy on domestic energy bills to fund hydrogen research and development.

This article looks at the ways hydrogen is made, the potential pitfalls and some of the applications the Government is considering. We then take a look at some of the fantasy economics for hydrogen production coming out of the Government and the proposed subsidy framework.

What is Hydrogen?

Hydrogen is the first element on the periodic table and so is the smallest and lightest element. In standard conditions it is a colourless, odourless, tasteless and non-toxic gas. Hydrogen is highly combustible and its small molecules can diffuse through many materials. Hydrogen is highly abundant in the Universe and on Earth. However, it is usually bound up with other elements such as oxygen to form water, or carbon to form methane or other compounds. This means that hydrogen can only ever be a secondary energy source or storage medium because it has to be manufactured from something else.

When hydrogen burns, it mixes with oxygen to form water vapour, with no CO2 emissions. This is why it is forming part of the Government’s Net Zero strategy. However, water vapour is also a greenhouse gas that according to NASA is a “critical component of climate change”. It is therefore unclear what the actual environmental benefits of using hydrogen as a fuel might be.

The Hydrogen Rainbow

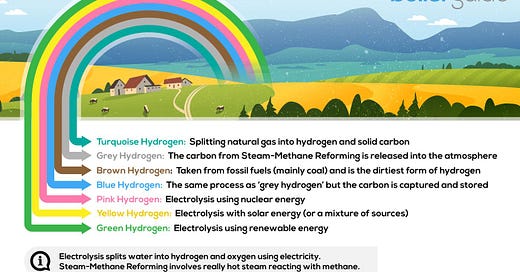

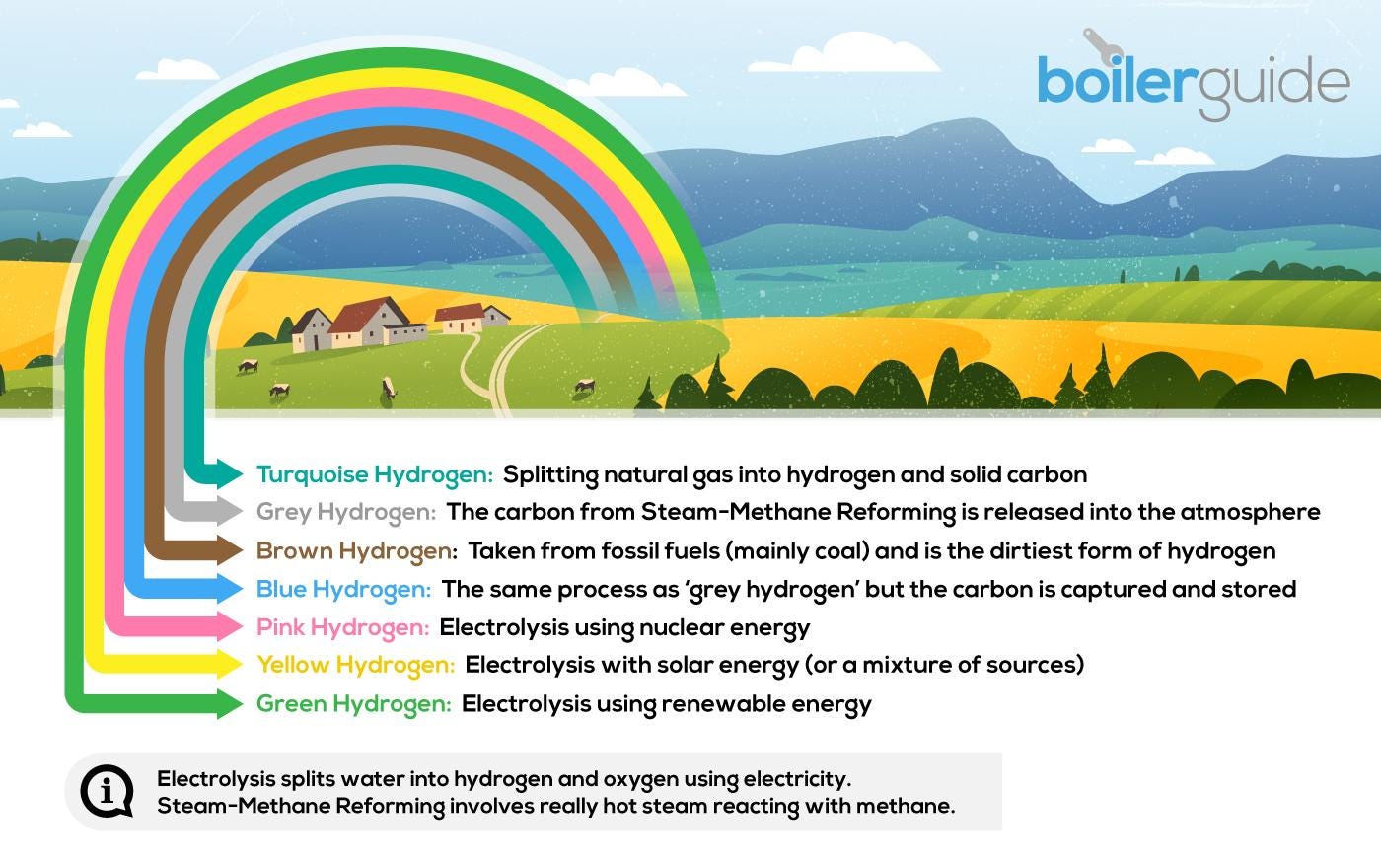

The energy industry has assigned colours to hydrogen produced by different means. See Figure 1 below, courtesy of Boiler Guide.

Black or brown hydrogen is produced from coal or lignite. Grey hydrogen is produced using steam methane reformation (SMR) without capturing the greenhouse gases emitted in the process. Almost all hydrogen today is produced using the grey, black or brown methods. Auto-thermal reforming (ATR) is an enhancement of the SMR process so it too maybe thought of as grey hydrogen.

Blue hydrogen is made in the same way as grey hydrogen except the CO2 emissions are captured and stored. This is touted as an environmentally friendly method of producing hydrogen. However, two American researchers concluded that the CO2-equivalent greenhouse gas emissions for blue hydrogen were only 9-12% less than grey hydrogen because some of the methane leaks in the production process. Even more surprisingly, they concluded that the total greenhouse gas footprint of blue hydrogen is 20% greater than burning coal or natural gas for heat.

According to the IEA, steam methane reformation is the most common way of making hydrogen today. The efficiency of the grey process is 60-70% according to the IEA and Royal Society. That efficiency falls for blue hydrogen where the CO2 produced in the process is captured and stored. This is because it takes energy to remove and store the CO2. The Government, in its Hydrogen cost report assumes 74% efficiency with Carbon Capture and Storage which is higher than other sources.

Most frequently, green hydrogen is produced by electrolysis using wind or solar power, although sometimes hydrogen produced from biomass is also referred to as green. Green hydrogen may not be all that green either because an Australian scientist has found that greenhouse gas emissions produced from making hydrogen from solar power are similar to those of grey hydrogen in real world conditions because of intermittency. Hydrogen from wind may suffer from the same problems as solar because wind power fluctuates at least as much as solar.

The most common form of electrolysis is PEM. Sometimes PEM stands for Proton Exchange Membrane and sometimes Polymer Electrolyte Membrane. There are other promising technologies such as Solid Oxide Electrolyte Cells (SOEC). The IEA (Table 3) says the current efficiency of PEM is 56-60% rising to 67-74% in the long term. They suggest efficiency of 74-81% for SOEC today, rising to 77-90% in the long term. The Royal Society expects efficiencies of 85-95% in the near future. The Government has a mid-point of around 80% for PEM electrolysis. A Parliamentary research note indicates 75% for PEM and 74-81% for SOEC.

Pink hydrogen is produced by electrolysis using nuclear power, sometimes also known as purple or red hydrogen. This might be a way of producing hydrogen without any significant greenhouse gases. There are proposals to produce hydrogen using heat and electricity from nuclear power plants, however there are none in operation yet.

Turquoise hydrogen is produced using an emergent technology called methane pyrolysis to create hydrogen and solid carbon. Yellow hydrogen is most commonly referred to as hydrogen produced using solar power, but the UNECE says yellow hydrogen is produced by nuclear power.

We can see that the CO2 emissions and overall system efficiency are dependent upon the energy source used. Clearly, using natural gas to generate electricity to then produce hydrogen would be very inefficient because modern CCGT gas turbines struggle to operate at a thermal efficiency above 50%, making the overall system efficiency around 37.5%.

Electricity from “renewable” electricity sources like wind or solar is more thermally efficient, but any electrolysis plant powered by renewables would have to contend with intermittent supply.

Because hydrogen is a secondary energy source, no matter which method is used to produce it, there are always going to be losses in the production process and further losses in compression and storage. For this reason, hydrogen should always be more expensive than the energy sources used to produce it.

Applications for Hydrogen

Today, hydrogen is mostly used in oil refining, ammonia production, methanol production and for making steel. However, the Government is getting excited about hydrogen because of a range of potential other uses such as:

Providing industrial heat

Generating electricity.

Replacing methane as a source of domestic heating.

Hydrogen powered vehicles.

Let us look at these areas in more detail.

Hydrogen for Industrial Heat

The most obvious question to ask here is: why bother? Why not simply burn methane instead and if CO2 is a problem, capture it as part of the process, just like when making blue hydrogen? The overall system efficiency will be better because energy has not been wasted in the intermediate steps of producing and storing hydrogen. Even if green hydrogen were to be used, the problems of the emissions from electrolysis would have to be solved. Pink hydrogen is a possibility, but if plants like that came on stream, it would be far more efficient to use the high temperature output of the nuclear power plant to provide the heat required directly and avoid the steps of making and storing the hydrogen.

Nevertheless, as Figure 2 shows, the Government’s hydrogen strategy is seeking to provide a £315m Industrial Energy Transformation Fund, a £20 million Industrial Fuel Switching Competition and a £10m Green Distilleries Fund to try and overcome these problems.

However, there is not much hope that any amount of funding will overcome the Laws of Thermodynamics.

Hydrogen for Generating Electricity

The same arguments apply to using energy to make hydrogen and then burning the hydrogen to produce electricity. Why not simply use the primary source to create electricity in the first place? The rationale used in the National Grid ESO’s Future Energy Scenarios (FES) report is essentially that green hydrogen could be produced and then stored when wind turbines or solar panels are producing more electricity than is required by the grid. The hydrogen could then be used to produce electricity when the wind is not blowing or the sun is not shining. They call this inter-seasonal storage.

However, storing the hydrogen brings its own problems. Currently, hydrogen is stored in relatively small quantities under high pressure in specially lined steel tanks. This method would not be suitable for large-scale inter-seasonal storage, so the Government is looking at large scale, long term storage in disused salt caverns. Phase 1 of the project run by Storengy and Inovyn describes a desktop feasibility study from 2019. Unfortunately, the project seems to have stalled because I have been unable to find any subsequent documentation on results or subsequent phases. In addition, SSE Thermal and Equinor are looking to repurpose caverns currently used to store natural gas to store hydrogen instead. They do not seem to have thought through where the natural gas we need to make hydrogen will be stored. The Government have now awarded funding to Project Hydus that is looking to store hydrogen in depleted Uranium. It is doubtful that there’s sufficient depleted Uranium available to provide the very large-scale storage that will be required.

Even if they can find a technology that works at scale, hydrogen storage is very expensive. National Grid ESO estimate that heavily used storage could add 20% to the cost of hydrogen, or much more with the strategic inter-seasonal storage they actually require (see Figure 3).

Not only is hydrogen more expensive to produce than its source fuels it’s very expensive and technically challenging to store it.

Hydrogen for Domestic Heating

One of the Government’s big ideas for hydrogen is to use it to replace natural gas for domestic heating. They even have pilot projects to trial the technology.

One example is H100Fife that is seeking to provide green hydrogen for 300 homes at a capital cost of some £32m, or more than £106,000 per household. This is due to come online during 2024. Participation in the project is entirely voluntary and it is not clear from their website how many people have signed up.

A proposal to convert 2,000 homes in Whitby, near Ellesmere Port to hydrogen is running into strong local opposition. Residents are concerned that they may be forced to convert to hydrogen against their will.

So, what are the concerns about hydrogen in domestic heating? First, there’s the overall efficiency argument outlined above. Hydrogen will always be more expensive and less efficient than the fuels used to make it because of the losses in manufacture and storage.

In addition, there are a number of concerns about safety. Hydrogen is highly combustible and additional safety measures would be needed to be taken to deal with this. A recent report from Arup for BEIS, as part of the Hy4Heat project recommended that “rooms with gas appliances or substantial pipework installed should have non-closable vents with equivalent area of 10,000 mm2”, or 10cm by 10cm. It seems rather odd to encourage everyone to invest heavily in home insulation and then force them to carve a 4-inch square hole in every room where there’s a hydrogen appliance like a hob, fire or boiler to let lots of heat out.

Further safety concerns surround a phenomenon known as “hydrogen embrittlement”. This is where tiny hydrogen molecules diffuse between grains of metals such as steel and act as stress concentrators and eventually cause the metal to fracture. This is an issue of significant concern and at least two projects are underway to test the impact of hydrogen being passed through the existing gas transmission network. The Future Grid project being run by National Gas is looking at a number of safety issues surrounding putting hydrogen in the national transmission network including embrittlement and leak testing. SGN is running a similar project called LTS Futures looking at the local transmission system. Future Grid is not due to complete fatigue testing until October 2024 and the LTS project is due to complete in 2025. However, John Butterworth, CEO of National Gas has committed to hydrogen being 2-5% of gas supply by 2025. It does seem rather odd to make this commitment before the safety testing has been completed.

Hydrogen Powered Vehicles

Some hydrogen-powered vehicles burn hydrogen in a modified internal combustion engine, others use hydrogen fuel cells to produce electricity to power the vehicle. The fuel cell is essentially electrolysis in reverse. Fuel cells can be up to 60% efficient which compares well with modern internal combustion engines with an efficiency of 30-35%. However, as discussed above, there are process inefficiencies in generating, storing and transporting the hydrogen, which brings down overall system efficiency.

If a widespread distribution network is in place, hydrogen powered cars could fill up in minutes, like with petrol or diesel which compares well to the extended charging times of electric vehicles.

However, there are a couple of significant drawbacks. The first is the level of investment required to build the distribution network, the second is the amount of hydrogen that would need to be stored (see above) to help manage the network through peaks and troughs. Third is the rarity metals like platinum and indium used as catalysts in fuel cells. Car manufacturers like Toyota and BMW are developing hydrogen-fuelled electric cars, but they are yet to catch on in a significant way.

One use-case that might be viable is large off-road vehicles like earth-moving equipment and cranes, where it is difficult to get reliable grid connections. JCB has built a number of its excavator-type vehicles to be powered by hydrogen fuelled internal combustion vehicles. Other potential applications include HGVs, buses, ships and maybe trains.

The Hydrogen Ladder

Energy analyst Michael Liebreich has produced what he calls the Hydrogen Ladder to describe the relative attractiveness of the different hydrogen applications or use-cases, see Figure 4.

It starts with row A that includes the easy applications for hydrogen that are in use today. As you descend the ladder to Row G, the applications become more difficult and less plausible. I have marked with red circles the applications prioritised by the Government.

The only applications he identifies at the relatively easy end of the scale are long-term storage and off-road vehicles, by which he means earth-moving equipment and the like. However, although he is relatively positive about long-term storage, he is very negative on power generation which is probably the main application requiring long term storage. As we saw above, even long term storage is running into technical difficulties.

Many of the other applications favoured by the Government are at the lower end of the ladder, meaning they are very difficult to achieve, or not worth bothering. These include domestic heating, industrial heat, trains, buses and HGVs.

It does beg the question why the Government is spending so much money on hydrogen when the feasible applications are very limited.

Economics of Hydrogen Production

Because hydrogen needs to be made using an industrial process, the Laws of Thermodynamics mean that the processes used to make it will always consume more energy than is liberated when hydrogen is burned as a fuel. Therefore, hydrogen will always be more expensive per MWh than the natural gas or the electricity used to produce it, unless of course the market is rigged in some way.

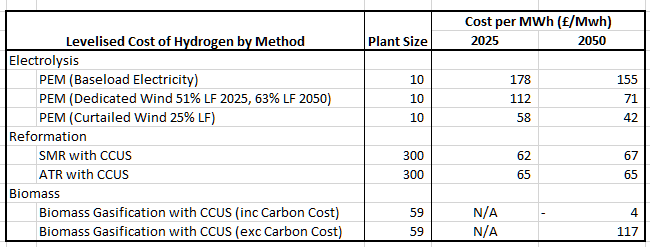

The Government has produced forecasts for hydrogen production costs by different methods. The most important numbers are summarised in Figure 5 below.

It is worth noting that all of the figures above exclude the costs of storage. We know from the FES report discussed above that costs will increase by at least 20% when storage is factored in. In all but some odd special cases discussed below, producing hydrogen by methane reformation with carbon capture and storage is cheaper than other production methods. 1,000MW SMR plants are slightly cheaper and 473MW biomass plants are quite a bit cheaper than the 59MW plants shown although still more expensive than SMR. The SMR costs include ~£6/MWh for storing the captured CO2.

The prices above compare to the central long run retail industrial gas prices forecast by the Government (Tables 4-8) of £25.80-£35/MWh in 2050.

The electrolysis numbers are based on some slightly dodgy assumptions. First, they assume over-optimistic load factors addressed here, which has the effect of bringing down the projected costs. Second, electricity costs for plants with dedicated windfarms attached are less than half the costs of getting the electricity from the grid. This more than offsets the additional costs of running the plants at less than full load to create a much lower overall cost.

They explain this by assuming that dedicated electrolysis plants will only be able to secure retail industrial electricity prices and not wholesale prices. They also explain that retail industrial electricity prices include “electricity policy costs”, which is odd because by 2050 the Government expects most grid electricity to be provided by renewables (see here Annex J). In other words, subsidies and grid balancing costs are going to be much higher than the costs of generating wind power.

However, the real twist of logic appears in their assumptions around hydrogen production from “curtailed electricity”. Curtailment happens when uncontrollable renewables such as wind and solar are able produce more than the grid can handle at a particular moment in time. At those times, the windfarms are asked to curtail their production. Because the grid is skewed to favour windfarms, in those circumstances, they are paid not to produce. However, those curtailment costs find their way into our bills through grid balancing costs. As Figure 6 shows, they assume the power required to produce hydrogen from curtailed electricity will be free.

In other words, electricity customers will pay the curtailment costs, but the windfarm continues to produce and directs its output to the hydrogen electrolysis plant.

They assume that an electrolysis plant operating on curtailed electricity will operate 25% of the time. This is nearly half the time of a windfarm operating at 51% load factor or 40% of the time of a windfarm operating at 63%. They position this as using electricity that would be “otherwise wasted.” Another way of looking at it is the grid is going to be so inefficient and so costly when it is operating mostly on renewables that they need find something to do with the surplus during the times there is excess power. They then pretend that power is free, even though consumers have paid the curtailment cost, to make hydrogen costs look cheap. An unscrupulous developer could own a wind farm and an electrolysis plant and claim the curtailment cost and charge the hydrogen plant for the electricity. Even with these financial contortions, it’s still more expensive than using gas as a fuel directly.

The biomass production method assumes that we will continue to cut down millions of tonnes of trees, turn them into wood pellets and produce hydrogen using the least thermally efficient process. One might expect this to be the most expensive method to produce hydrogen. But magically, the costs are actually negative. They achieve this conjuring trick by assuming that hydrogen made from biomass using carbon capture produces negative emissions and therefore producers can sell carbon credits and voilà the hydrogen costs less than nothing to make. In fact, they assume the producer will get back in carbon credits nearly 10 times the cost to store the CO2 produced (see Figure 7).

It is totally absurd.

We can now see why hydrogen produced from grid electricity would be so expensive. The “policy costs” include all of these subsidies and distortions to make the expensive things they want to do appear to cost very little or less than nothing.

Subsidy Upon Subsidy – Low Carbon Hydrogen Business Model

That brings us on to the subsidy framework. The Government have produced a Hydrogen Production Business Model and in it they describe the costs that will be allowed to be included in the strike price. This includes “input energy costs” and a guaranteed return on capital as shown in Figure 8 below.

In essence, operators with both windfarms and electrolysers could receive a subsidised, guaranteed price for the electricity they generate at the windfarm and then charge that price to the electrolyser and receive a further subsidised price for the hydrogen and a guaranteed return on top. This is white-collar welfare on steroids. It is time to pop the hydrogen bubble.

If you have enjoyed this article, please sign-up to receive more content and share it with your family, friends and colleagues.

Please share David’s original post and, if you don’t already, consider subscribing to his Substack:

Related links: